Research

Research Areas

Using DNA as an engineering material, we create self-assembling mechanical systems with applications in both advanced manufacturing and bioengineering.

By building at the scale of proteins and biological machines, we can develop nanometer-scale sensors and actuators, structures and machines with extreme mechanical properties and programmable nanoscale platforms that can interface both biotic and abiotic systems (i.e. cells and electronics).

This work has been supported by generous funding from the National Science Foundation, the Air Force Office of Scientific Research, the National Institutes of Health, the Samuel and Emma Winters Foundation, the Manufacturing Futures Institute at CMU, the DSF Charitable Foundation and the Donald L. and Rhonda Struminger Faculty Fellowship.

Bio-inspired Micro- and Nanosystems

Magnetically-actuated swimming microrobots with flexible DNA components

Synthetic "armor" for protection and mechanical modulation of living cells

Nanoscale force sensors

Biomanufacturing and Nanomanufacturing

Manufacturing of DNA origami superstructures for robotics

Automated approaches for the design and production of DNA nanostructures

Machine learning and process innovations for maximizing manufacturing yield of DNA superstructures

Top-down/bottom-up microfabrication approaches for creating microscale segmented robotic systems

Biotic and abiotic interfaces for nucleic acid nanotechnology

Programming membrane interactions and uptake of DNA nanoparticles

Nondisruptive labeling of human blood platelets for biomechanics studies

Peptide nucleic acid nanotechnology: a water-soluble and nuclease-resistant nanomaterial

Laboratory and Equipment

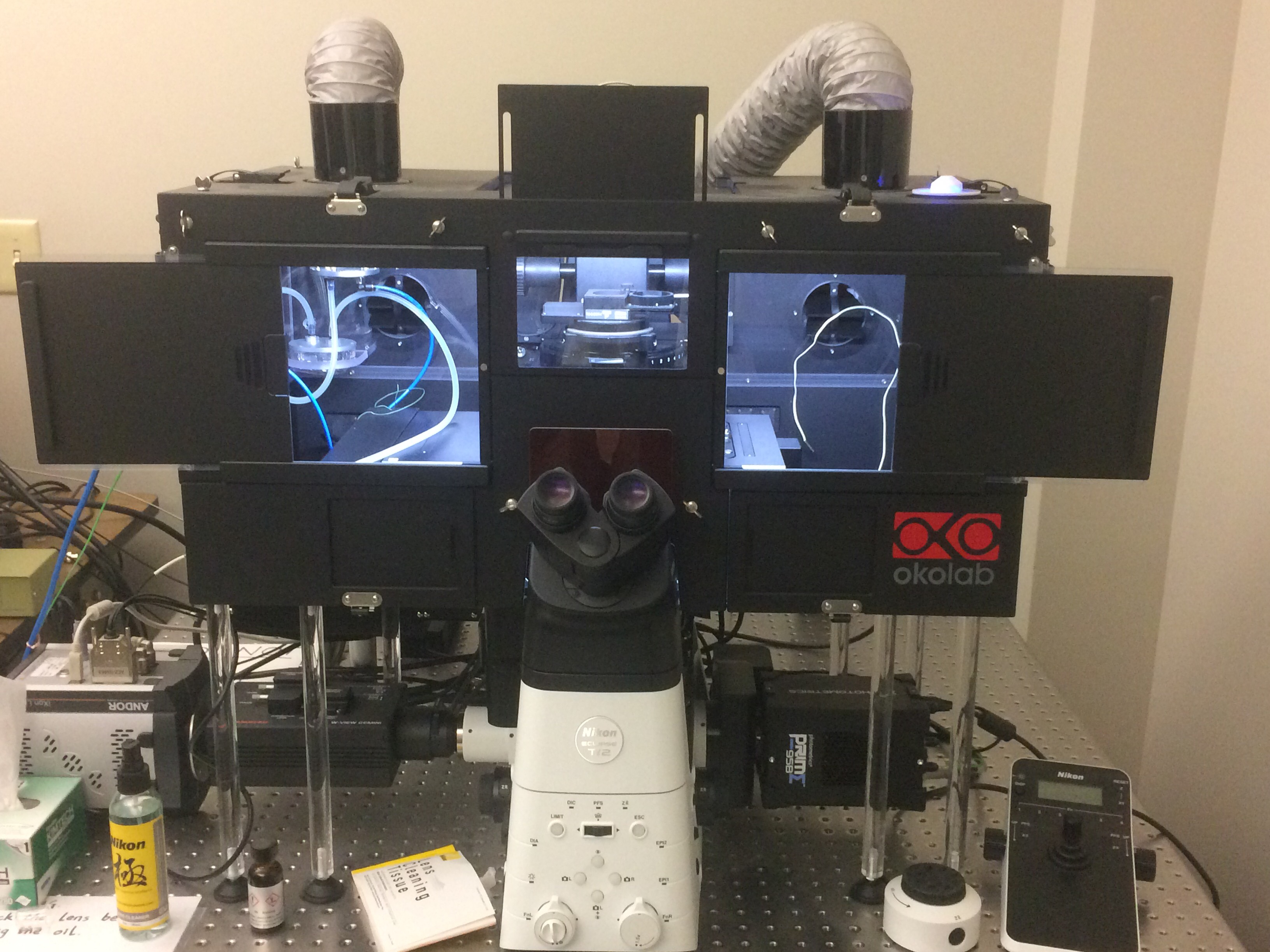

Nikon Eclipse Ti2-E TIRF Microscope

With the support of a Dean's Equipment Grant, we have acquired an environmentally-controlled Nikon TIRF microscope. The system was installed summer 2017 and is now fully operational. CMU researchers interested in using this tool should contact the MMBL to arrange for training.

Motorized inverted microscope with 25mm field of view and Perfect Focus System 4

Motorized epifluorescence turret with following filter cubes: 350, 488, 546, 647 nm

DIC at 10x, 20x, 60x, 100x

Plan APO objectives at 10x, 20x, 100x (oil)

APO TIRF objective at 60x and 100x (both oil objectives)

TIRF with following laser lines: 488/561/640 nm

EMCCD camera: Andor DU897 LIFE with Hamamatsu Gemini Emission Splitter

sCMOS camera: Photometrics PRIME95B

Software: NIS Elements

OKO lab environmental control system with interlocks for laser safety

Miniscanner for Optogenetics, Stimulation, Activation and Bleaching equipped with following laser lines: 405/488/561 nm.

Nikon Ti2e TIRF Microscope

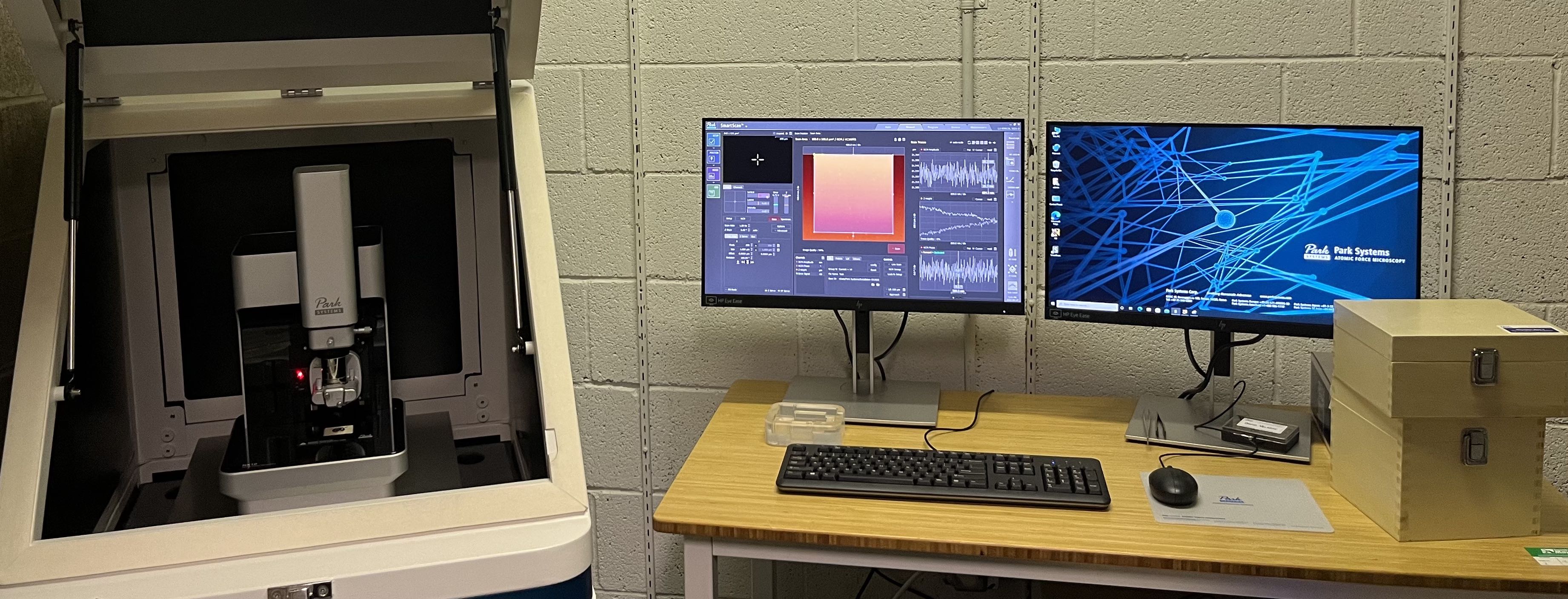

Park NX10 AFM with SICM Module

The NX10 Atomic Force Microscope (AFM) is based on a flexure-based design which decouples XY and Z. With an achievable scan range of 100 μm in XY and 15 μm and 30 μm (with extended Z as we have configured to accommodate cell imaging) The Scanning Ion Conductance Microscopy (SICM) module makes this scanning probe instrument unique and expands the functionality of the NX10 to a wider range of applications including analytical chemistry, cell biology, electrophysiology and neuroscience. This instrument was funded by AFOSR DURIP award #FA9550-22-1-0147. For further information, see the detailed NX10 system specifications.

Park NX10 AFM with SICM Module

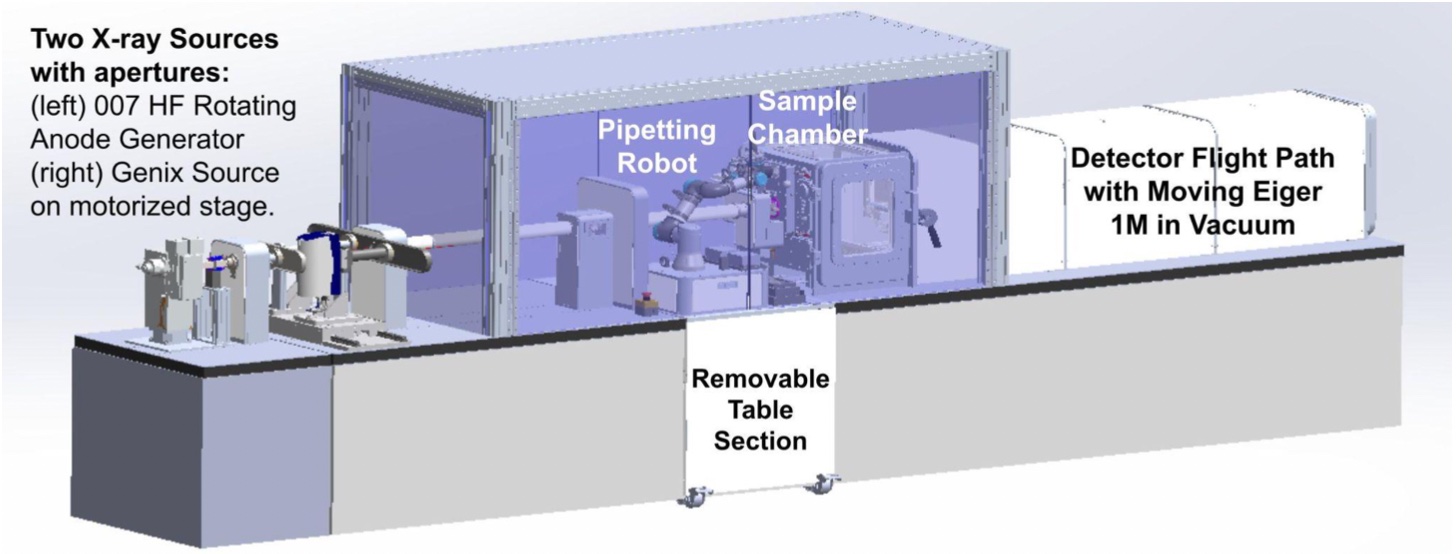

Automated SAXS/WAXS Instrument

Coming late Spring 2022 to the Materials Characterization Facility at CMU: A new, automated SAXS/WAXS Instrument supported by NSF MRI Award #2117523. This instrument will support the development of cutting-edge nanostructured materials that have keys features ranging in size from Angstroms to hundreds of nanometers. To enable in situ and in operando characterization of structural properties, this custom, automated Xenocs Xeuss 3.0 x-ray scattering system will enable high-throughput studies at a variety of length scales. For further information, see the detailed Xeuss 3.0 system specifications at the Materials Characterization Facility website.

Xenocs Xeuss 3 SAXS/WAXS instrument